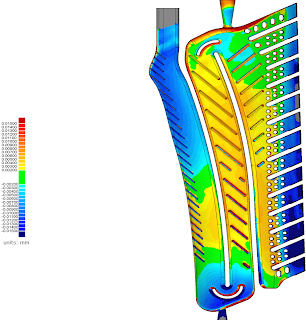

Cored airfoil parts are among the most complex castings in the world and therefore are among the most difficult to inspect, one aspect of the complexity is the largely unknown geometry of the actual injection molded ceramic core; until now. Level 3 Inspection can use White Light Scanning (WLS) with computer-aided-inspection (CAI) to compare the ceramic core to the CAD model, other cores and the core die. This technology gives our customers a new and profound insight into the size shape and geometric conformance of cores that they have never had before. By inspecting and perfecting the ceramic core (and die) Level 3 can help their customers significantly reduce wall thickness and other issues commonly associated with cored castings.

Level 3 Inspection’s SmartCompare & SmartInspect process gives their customers the ability to identify problems with a particular area of the part and focus efforts to improve problem areas without spending time and resources on areas that are known to be conforming. This is especially helpful when dealing with injection molded components, such as ceramic cores. The ability to quickly compare the product of the mold to the nominal CAD model as well as the ability to compare the products of multiple molds gives Level 3 Inspection’s customers an advantage in regard to quality and time to market.

The Level 3 approach replaces traditional plate inspection or a CMM system with WLS, which can capture and calculate precise 3D coordinates for millions of points in seconds.

Contact us today to start getting superior inspection results in shorter time with easier understanding leading to higher confidence