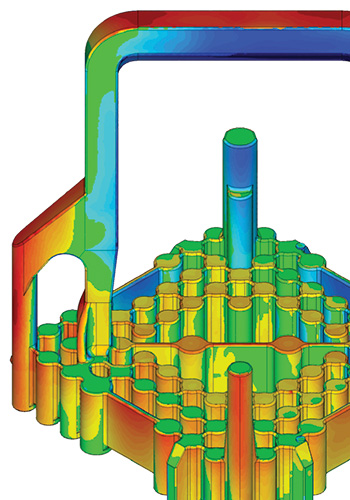

Computer Aided Inspection (Advanced Dimensional Layout Inspection)

CAI can eliminate the requirement for generating 2D drawings for parts and tools, which can save hundreds of engineering hours. It places the verification and inspection process into the 3D digital realm, where it can be fully integrated into existing CAD/CAM/CAE processes. This will allow manufacturers to reap greater benefits from their CAD/CAM/CAE investments and bring them closer to the promise Six Sigma. The biggest obstacle to CAI acceptance is the inertia caused by familiar ways of doing things.

Unwillingness to take a risk is always a deterrent to innovation. But, the difference between CAI and earlier digital processes is that there is much less risk. CAI technologies complement, rather than replace, the CAD/CAM/CAE systems manufacturers already have in place. Early adopters of CAI will get a head start in establishing processes whose benefits will only multiply with time.

CAI software will become a mainstream application and an essential part of the digital product development cycle. Pushing quality inspection into earlier phases of the development cycle will speed product development and ensure greater quality. As supplier networks continue to expand and products are increasingly differentiated according to quality, how well a company implements the inspection process can be a make or break factor in the marketplace. CAI is beginning the same way as most new technologies. The innovators are relatively small companies without extensive marketing resources to penetrate deeper into large manufacturing operations. System integrators and consultants are needed to customize the new CAI technologies and integrate them into existing digital manufacturing processes.

Current methods of ballooning blueprints, generating reports (L3I Dimensions)

Current methods of performing analysis (GOM Inspect or Geomagic)

Scan and Dimensional data management (look for cut and paste, errors induction)

Potential solution: L3I Dimensions